Utility knives are indispensable tools in both professional settings and everyday tasks. Among the various types of utility knives, the straight blade utility knife stands out for its versatility and efficiency. This article will explore the features, benefits, and applications of straight blade utility knives, particularly focusing on their significance in various industries and how Nxtools, a leading utility knife manufacturer, excels in producing high-quality options.

Understanding Utility Knives

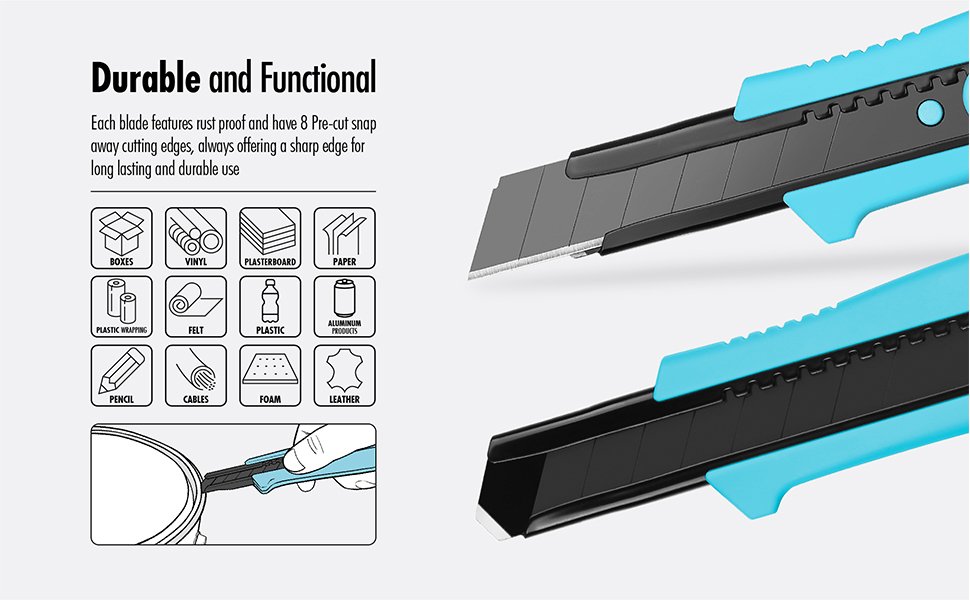

Utility knives are designed for cutting a wide range of materials, from cardboard and drywall to ropes and plastics. They typically feature:

– A sharp, replaceable blade: This allows for easy maintenance and ensures optimal cutting performance.

– An ergonomic handle: Designed for comfort during extended use, reducing hand fatigue.

– Safety features: Many models include retractable blades or safety guards to prevent accidental injuries.

Why Choose a Straight Blade Utility Knife?

Straight blade utility knives offer several advantages that make them a preferred choice among professionals and DIY enthusiasts.

– Precision Cutting: The straight edge allows for clean, straight cuts, making it ideal for tasks that require accuracy, such as trimming drywall or cutting through cardboard.

– Ease of Sharpening: Straight blades are easier to sharpen compared to serrated blades, ensuring they maintain their cutting edge longer.

– Versatility: They can be used across various applications, from construction to culinary tasks.

Applications of Straight Blade Utility Knives

Straight blade utility knives are utilized in numerous fields:

– Construction: Essential for cutting drywall, insulation materials, and other building supplies.

– Packaging: Commonly used in warehouses for opening boxes and cutting strapping materials.

– Culinary Arts: Chefs often use utility knives for precise slicing tasks in food preparation.

– Crafting: Hobbyists utilize these knives for intricate cuts in paper, fabric, and other crafting materials.

– Automotive: Technicians use utility knives to cut through various materials during repairs or installations.

Nxtools: A Leading Utility Knife Manufacturer

Nxtools has established itself as a prominent utility knife manufacturer based in Yucheng, Shangqiu—known as the hardware tools capital of China. Their modern manufacturing facility specializes in producing high-quality hand tools, including straight blade utility knives.

@nx.tools

Quality Assurance

Nxtools emphasizes quality control throughout its production process. Each knife undergoes rigorous testing to ensure durability and performance. The company sources high-grade materials to manufacture blades that resist dulling and corrosion over time.

Innovative Designs

The company continuously innovates its product line to incorporate ergonomic designs and advanced safety features, addressing the needs of various industries. For instance, many Nxtools models come with soft-grip handles that enhance user comfort while minimizing slippage during use.

Choosing the Right Straight Blade Utility Knife

When selecting a straight blade utility knife, consider the following factors:

– Blade Material: High-carbon stainless steel blades offer superior sharpness and corrosion resistance. Some models may also feature titanium coatings for added durability.

– Handle Design: Look for handles that provide a secure grip and comfort during prolonged use. Textured grips can prevent slipping even when working in wet conditions.

– Safety Features: Opt for models with retractable blades or locking mechanisms to enhance safety. Some knives even come with built-in safety guards that protect fingers while cutting.

– Blade Length: Different tasks may require different blade lengths. Longer blades can cut through thicker materials more easily, while shorter blades offer better control for detailed work.

Maintenance Tips for Utility Knives

To ensure longevity and performance:

– Regularly replace dull blades: Dull blades require more force to cut, increasing the risk of accidents. Always keep spare blades on hand for quick replacements.

– Clean after use: Wipe down blades to remove debris and prevent corrosion. A simple cloth can suffice; however, avoid using abrasive materials that could scratch the blade surface.

– Store safely: Keep utility knives in designated sheaths or holders to protect the blade and prevent injuries. Magnetic strips or wall-mounted racks can be effective storage solutions.

Comparing Straight Blade Utility Knives with Other Types

To understand the unique benefits of straight blade utility knives better, it’s essential to compare them with other types of utility knives:

| Feature | Straight Blade Utility Knife | Retractable Blade Utility Knife | Serrated Blade Utility Knife |

|---|---|---|---|

| Cutting Precision | High | Moderate | Low |

| Ease of Sharpening | Easy | Moderate | Difficult |

| Versatility | High | Moderate | Low |

| Safety Features | Varies | Generally high | Varies |

| Best Use | General cutting tasks | Quick cuts | Cutting fibrous materials |

This comparison highlights how straight blade utility knives excel in precision and versatility compared to their counterparts.

Frequently Asked Questions (FAQs)

1. What is a straight blade utility knife?

– A straight blade utility knife features a long, flat blade designed for precision cutting tasks across various materials.

2. How do I sharpen my utility knife?

– Use a sharpening stone or file at a consistent angle along the edge of the blade until it reaches your desired sharpness.

3. Are there safety features in modern utility knives?

– Yes, many models include retractable blades or safety guards to minimize the risk of injury.

4. Can I use a straight blade utility knife for food preparation?

– Absolutely! They are versatile enough to be used in kitchens for slicing fruits, vegetables, and meats.

5. What should I look for when buying a utility knife?

– Consider factors like blade material, handle comfort, safety features, and overall build quality when selecting a utility knife.

6. How often should I replace my utility knife blades?

– Replace blades whenever they become dull or damaged; this ensures optimal performance and safety during use.

7. Can I use my utility knife outdoors?

– Yes! Straight blade utility knives are suitable for outdoor tasks such as camping or gardening; just ensure you choose a model with weather-resistant materials.

8. What is the best way to store my utility knife?

– Store your utility knife in a protective sheath or holder away from children’s reach; consider using magnetic strips or toolboxes designed for safe storage.

9. Are Nxtools’ products eco-friendly?

– Nxtools is committed to sustainable practices; they utilize environmentally friendly manufacturing processes whenever possible.

10. How do I know which size knife is right for me?

– The right size depends on your specific needs; consider what materials you’ll be cutting most frequently when making your selection.

Conclusion

In conclusion, straight blade utility knives are vital tools that enhance efficiency across multiple sectors. With Nxtools as a leading manufacturer providing high-quality options tailored to various needs, these knives are an essential addition to any toolbox. Their precision cutting capabilities combined with user-friendly designs make them invaluable for both professionals and DIY enthusiasts alike.