In the world of construction, renovation, and beyond, precision is paramount. For years, achieving perfect levels and alignments required painstaking manual measurements and a healthy dose of patience. But what if there was a tool that could streamline the process, ensuring accuracy and efficiency with ease? Nxtools, a leading industrial and trading company based in Yucheng, Shangqiu – the hardware tools capital of China – has been at the forefront of providing cutting-edge solutions for professionals and DIY enthusiasts alike. Today, we delve into the game-changing potential of 360-degree laser levels.

Are 360-degree laser levels truly a revolutionary advancement, or just another hyped-up gadget? In this comprehensive guide, we’ll explore the ins and outs of these innovative tools, examining their benefits, applications, key features, and how they can transform your projects. As a dedicated laser level manufacturer, Nxtools is committed to providing you with the knowledge and tools you need to succeed. We’ll also showcase our own line of 360-degree laser levels, highlighting the quality and innovation that define the Nxtools brand. Join us as we explore the exciting world of laser level technology and discover how it can elevate your work to new heights.

Understanding Laser Levels: A Foundation

To fully appreciate the advancements offered by 360-degree laser levels, it’s essential to understand the fundamentals of laser level technology.

What is a Laser Level?

A laser level is a precision instrument that projects a laser beam to establish a perfectly horizontal or vertical plane. This plane serves as a visual reference for aligning objects, transferring points, and ensuring accuracy in various tasks.

Basic Components:

Laser Diode: The heart of the laser level, responsible for generating the laser beam.

Leveling Mechanism: Ensures the laser beam is perfectly horizontal or vertical. This can be manual (requiring adjustment by the user) or automatic (self-leveling).

Housing: Protects the internal components and provides a stable base for the instrument.

Power Source: Typically batteries, providing the energy to operate the laser diode and leveling mechanism.

Traditional vs. Modern Laser Levels

Traditional spirit levels, while reliable, rely on manual reading of bubbles and are limited in range and application. Modern laser levels offer several advantages:

Increased Accuracy: Laser beams provide a precise and consistent reference point.

Extended Range: Laser levels can project beams over considerable distances, making them suitable for large-scale projects.

Self-Leveling Capabilities: Automatic leveling mechanisms save time and ensure accuracy, even on uneven surfaces.

Versatility: Laser levels can be used for a wide range of applications, from simple home improvements to complex construction projects.

The Rise of 360-Degree Laser Levels

What Distinguishes a 360-Degree Laser Level?

Unlike traditional laser levels that project a single line or a limited fan of laser lines, a 360-degree laser level projects a continuous horizontal or vertical laser line around the entire room or area. This creates a complete reference plane, eliminating the need to constantly reposition the level.

Benefits and Advantages

The unique design of 360-degree laser levels offers several key advantages:

Enhanced Efficiency: Cover an entire room with a single setup, saving time and effort.

Improved Accuracy: The continuous laser line provides a consistent reference point, minimizing errors.

Increased Versatility: Suitable for a wider range of applications, from installing drop ceilings to aligning tiles.

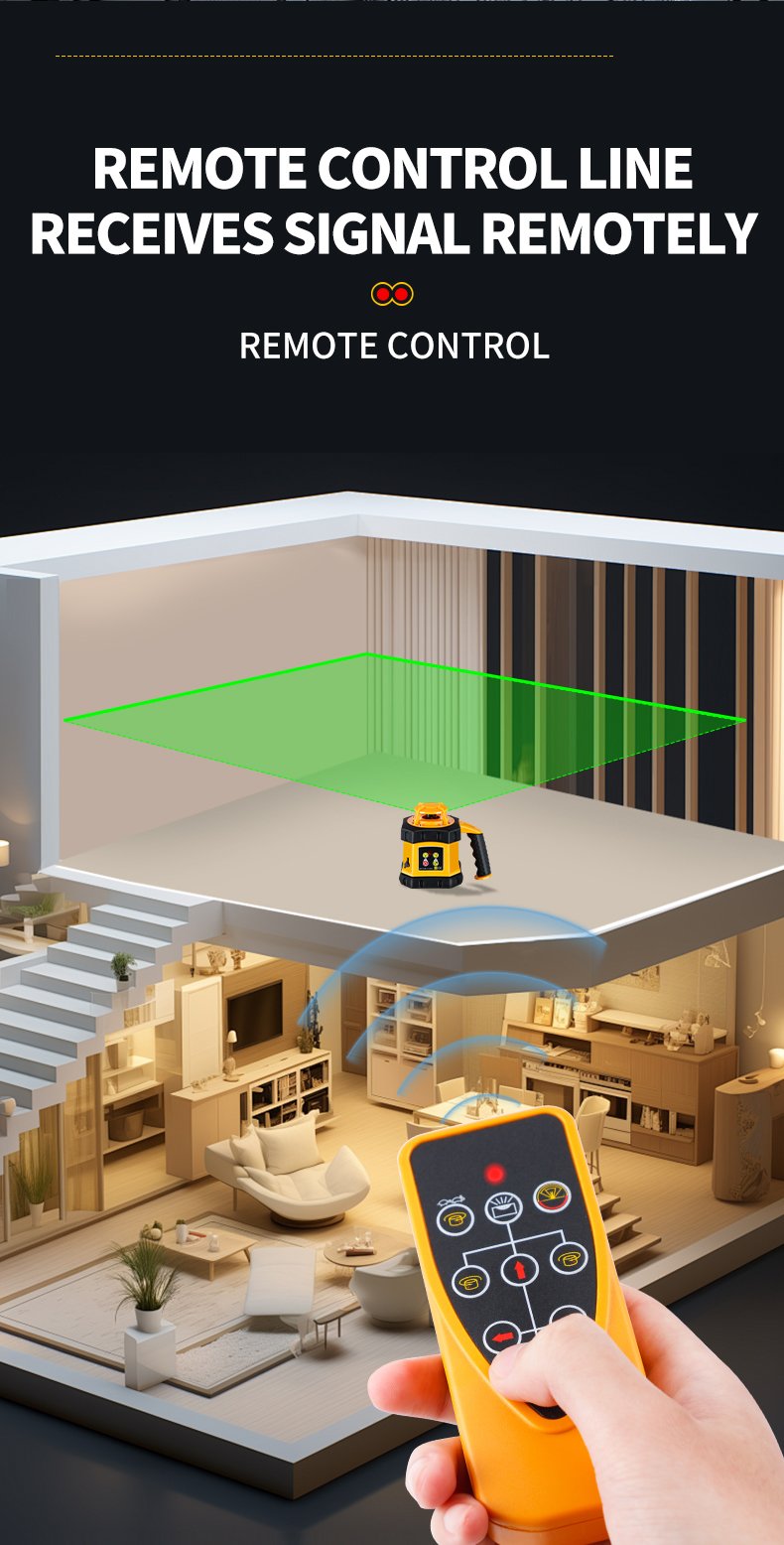

Greater Convenience: The self-leveling feature and remote control operation (in some models) make them incredibly easy to use.

One-Person Operation: Many tasks can be performed by a single person, reducing labor costs.

Applications Across Industries

360-degree laser levels have become indispensable tools in a variety of industries:

Construction

Leveling Foundations: Ensuring a perfectly level base for buildings.

Installing Drop Ceilings: Creating a consistent and level ceiling grid.

Aligning Walls and Partitions: Ensuring walls are straight and plumb.

Setting Door and Window Frames: Guaranteeing proper alignment.

Transferring Points: Accurately transferring reference points from floor to ceiling or wall to wall.

Home Renovation

Hanging Pictures and Shelves: Achieving perfectly aligned displays.

Installing Tile: Ensuring level and even tile installations.

Wallpapering: Creating straight and consistent wallpaper seams.

Installing Cabinets: Aligning cabinets for a professional finish.

DIY Projects: Making various home improvement tasks easier and more accurate.

Landscaping

Leveling Ground: Preparing surfaces for patios, walkways, and gardens.

Setting Fence Posts: Ensuring fence posts are aligned and level.

Creating Slopes for Drainage: Establishing proper drainage gradients.

Building Retaining Walls: Aligning retaining wall blocks for structural integrity.

Other Industries

HVAC Installation: Aligning ductwork and piping.

Electrical Work: Ensuring accurate placement of outlets and fixtures.

Plumbing: Leveling pipes for proper drainage.

Manufacturing: Aligning machinery and equipment.

Key Features to Look For

When choosing a 360-degree laser level, consider these essential features:

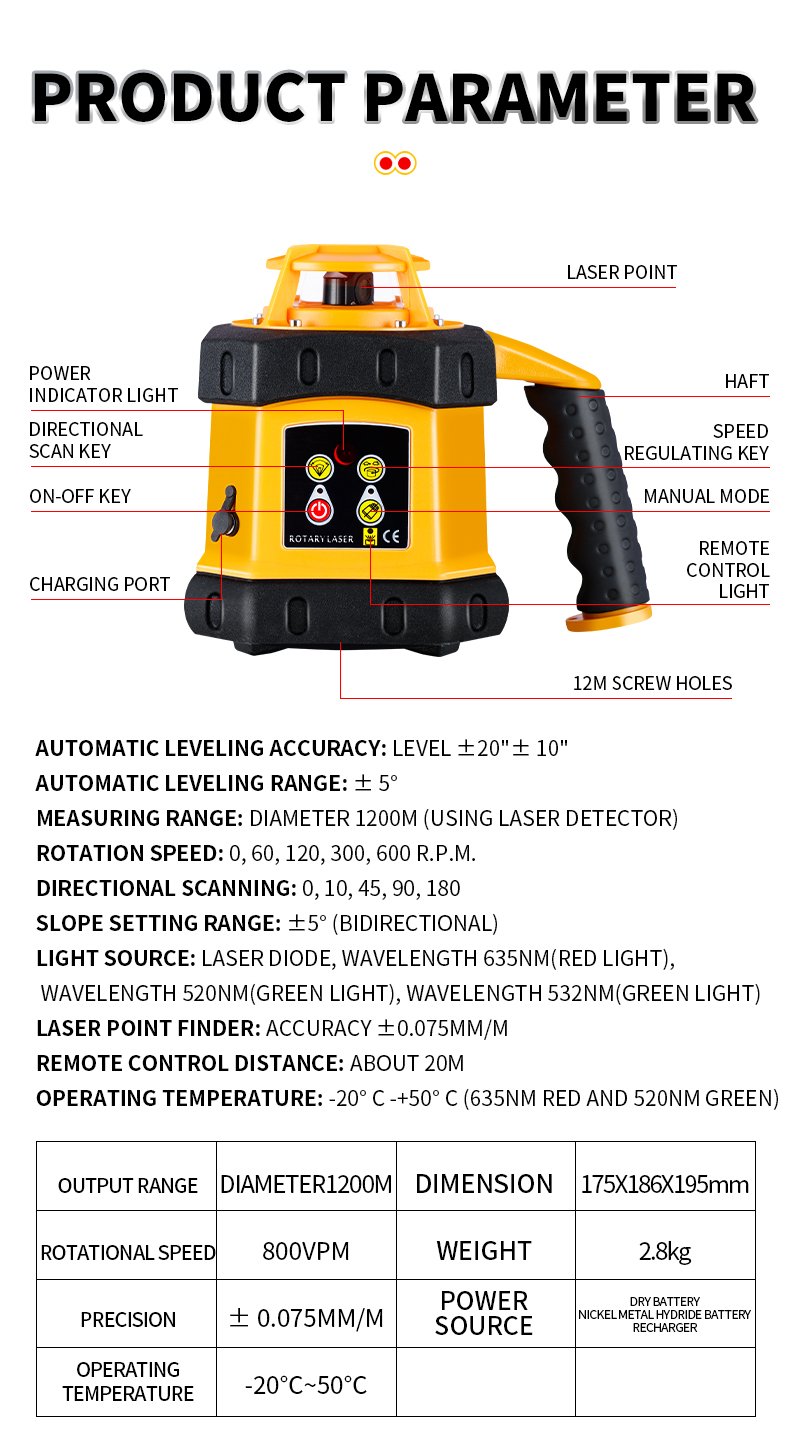

Accuracy

The accuracy of a laser level is measured in millimeters per meter (mm/m) or inches per feet (in/ft). A lower number indicates greater accuracy. For professional applications, look for levels with an accuracy of ±2mm/10m or better.

Range

The range of a laser level is the maximum distance over which the laser beam can be reliably detected. Choose a range that suits the size of your typical projects. Some models offer extended range with the use of a laser detector.

Self-Leveling

Self-leveling laser levels automatically compensate for slight variations in the surface, ensuring a perfectly level beam. Look for levels with a wide self-leveling range (e.g., ±5 degrees).

Battery Life

Consider the battery life of the laser level, especially if you plan to use it for extended periods. Some models offer rechargeable batteries or compatibility with standard alkaline batteries.

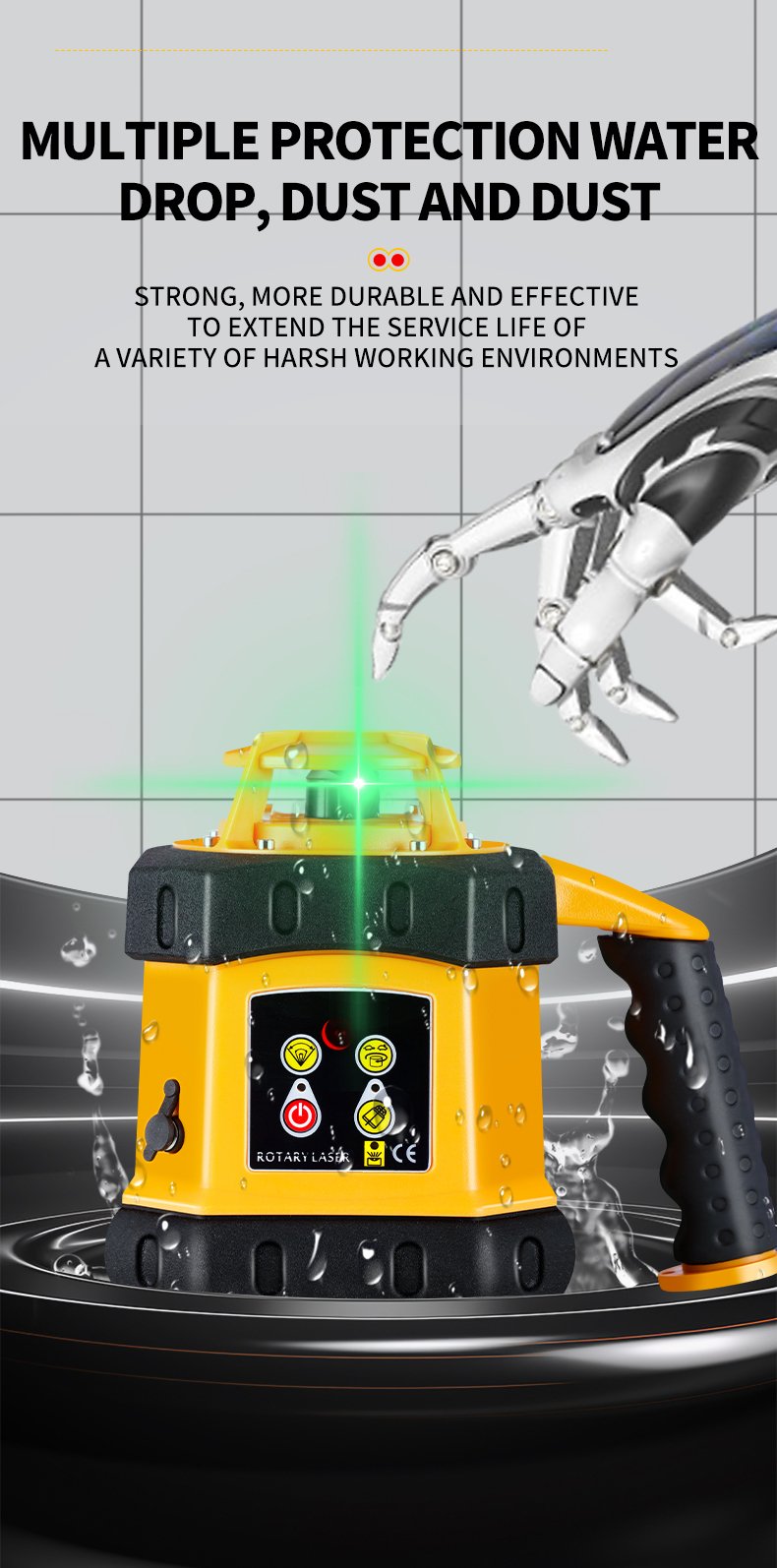

Durability

Choose a laser level with a robust housing that can withstand the rigors of job site use. Look for models with IP ratings (Ingress Protection) that indicate resistance to dust and water.

Beam Color

Laser levels typically use red or green beams. Green beams are generally easier to see in bright light conditions, but they may consume more battery power.

Choosing the Right 360-Degree Laser Level: A Buyer’s Guide

Selecting the perfect 360-degree laser level depends on your specific needs and budget. Here’s a guide to help you make the right choice:

Project Requirements

Consider the types of projects you’ll be undertaking. For small home improvement tasks, a basic model may suffice. For professional construction work, you’ll need a more accurate and durable level with a longer range.

Budget

360-degree laser levels range in price from a few hundred dollars to several thousand. Determine your budget and look for models that offer the best combination of features and value within your price range.

Brand Reputation

Choose a laser level from a reputable manufacturer known for quality and reliability. Read online reviews and ask for recommendations from other professionals.

Nxtools: Your Trusted Laser Level Manufacturer

Nxtools is committed to providing high-quality, innovative tools that meet the needs of professionals and DIY enthusiasts worldwide. As a leading laser level manufacturer in China, we combine advanced technology with rigorous quality control to ensure our products deliver exceptional performance and durability.

Nxtools’ Commitment to Quality and Innovation

Our 360-degree laser levels are designed with precision and built to last. We use only the finest materials and components, and our products undergo extensive testing to ensure they meet the highest standards of accuracy and reliability.

Showcase Nxtools’ 360-Degree Laser Level Products

Nxtools Model HS-206:

Unique Selling Points

Nxtools’ 360-degree laser levels stand out from the competition thanks to:

Superior Accuracy: Our laser levels are calibrated to the highest standards, ensuring precise measurements every time.

Exceptional Durability: Built to withstand the toughest job site conditions.

User-Friendly Design: Easy to set up and operate, even for beginners.

Excellent Value: We offer competitive pricing without compromising on quality.

Dedicated Customer Support: Our team is always available to answer your questions and provide technical assistance.

Tips and Tricks for Optimal Use

Setting Up Your Laser Level

Place the laser level on a stable surface or tripod.

Ensure the surface is within the self-leveling range of the instrument.

Allow the laser level to self-level before taking measurements.

Use a laser detector in bright light conditions or over long distances.

Troubleshooting Common Issues

Laser beam is not visible: Check the battery level and ensure the laser is turned on. Use a laser detector if necessary.

Laser beam is not level: Ensure the laser level is within its self-leveling range. Check for obstructions that may be interfering with the leveling mechanism.

Laser beam is flickering: This may indicate a low battery or a problem with the laser diode. Contact Nxtools customer support for assistance.

Maintenance

Clean the laser lens regularly with a soft, lint-free cloth.

Store the laser level in a dry, safe place when not in use.

Replace batteries as needed.

Have the laser level professionally calibrated periodically to maintain accuracy.

The Future of Laser Level Technology

Emerging Trends

The future of laser level technology is bright, with several exciting trends on the horizon:

Increased Accuracy: Expect to see even more accurate laser levels with tighter tolerances.

Integration with Mobile Devices: Laser levels that can connect to smartphones and tablets for data logging and remote control.

3D Laser Scanning: Laser levels that can create 3D models of spaces for BIM (Building Information Modeling) applications.

Improved Battery Technology: Longer-lasting batteries and more efficient power management systems.

AI-Powered Features: Laser levels that can automatically detect and correct errors, and provide intelligent guidance to users.

Nxtools’ Vision for the Future

Nxtools is committed to staying at the forefront of laser level technology. We are constantly investing in research and development to create innovative products that meet the evolving needs of our customers. As a dedicated laser level manufacturer, we envision a future where laser levels are even more accurate, versatile, and user-friendly, empowering professionals and DIY enthusiasts to achieve exceptional results with ease.

Conclusion

360-degree laser levels are undoubtedly a game changer for a wide range of projects. Their ability to project a continuous laser line around an entire room or area provides unparalleled efficiency, accuracy, and versatility. Whether you’re a seasoned construction professional or a DIY enthusiast tackling home improvement projects, a 360-degree laser level can significantly enhance your workflow and ensure exceptional results.

As a trusted laser level manufacturer, Nxtools offers a range of high-quality 360-degree laser levels designed to meet the needs of any project. Visit our website today to explore our product line and discover how Nxtools can help you achieve precision and efficiency in your work. Contact us to learn more about our products and find the perfect laser level for your needs.

FAQ

Q1: What is the difference between a red beam and a green beam laser level?

A: Green beam laser levels are generally easier to see in brighter lighting conditions compared to red beam laser levels. However, green beam lasers typically consume more battery power.

Q2: How often should I calibrate my laser level?

A: It is recommended to calibrate your laser level at least once a year, or more frequently if it is used heavily or subjected to harsh conditions.

Q3: What is IP rating, and why is it important?

A: IP (Ingress Protection) rating indicates the level of protection a device has against dust and water. A higher IP rating means greater protection. It is important to choose a laser level with an appropriate IP rating for the environment in which it will be used.

Q4: Can I use a 360-degree laser level outdoors?

A: Yes, but the visibility of the laser beam may be reduced in bright sunlight. Using a laser detector can significantly improve visibility and extend the range of the laser level outdoors.

Q5: What is self-leveling range, and why is it important?

A: Self-leveling range is the maximum degree to which a laser level can automatically compensate for an uneven surface. A wider self-leveling range allows the laser level to be used on more varied terrain without manual adjustments.