Laser levels are essential tools for ensuring accuracy in a variety of projects, from simple home improvements to complex construction tasks. Proper leveling is critical for achieving precise results. This guide provides a detailed explanation of how to level a laser level, incorporating best practices and troubleshooting tips.

1. Understanding the Importance of Leveling

Accuracy is Key: A laser level projects a beam of light to establish a horizontal or vertical plane. If the level isn’t properly calibrated, the projected line will be skewed, leading to inaccurate measurements.

Time and Cost Savings: Accurate leveling prevents errors and rework, saving time and money.

Professional Results: Whether you’re a DIY enthusiast or a professional contractor, proper leveling ensures professional results.

2. Types of Laser Levels

Self-Leveling Laser Levels: These automatically compensate for minor surface irregularities within a specified range.

Manual Laser Levels: These require manual adjustment of leveling screws or knobs until the bubble vial indicates a perfectly horizontal position.

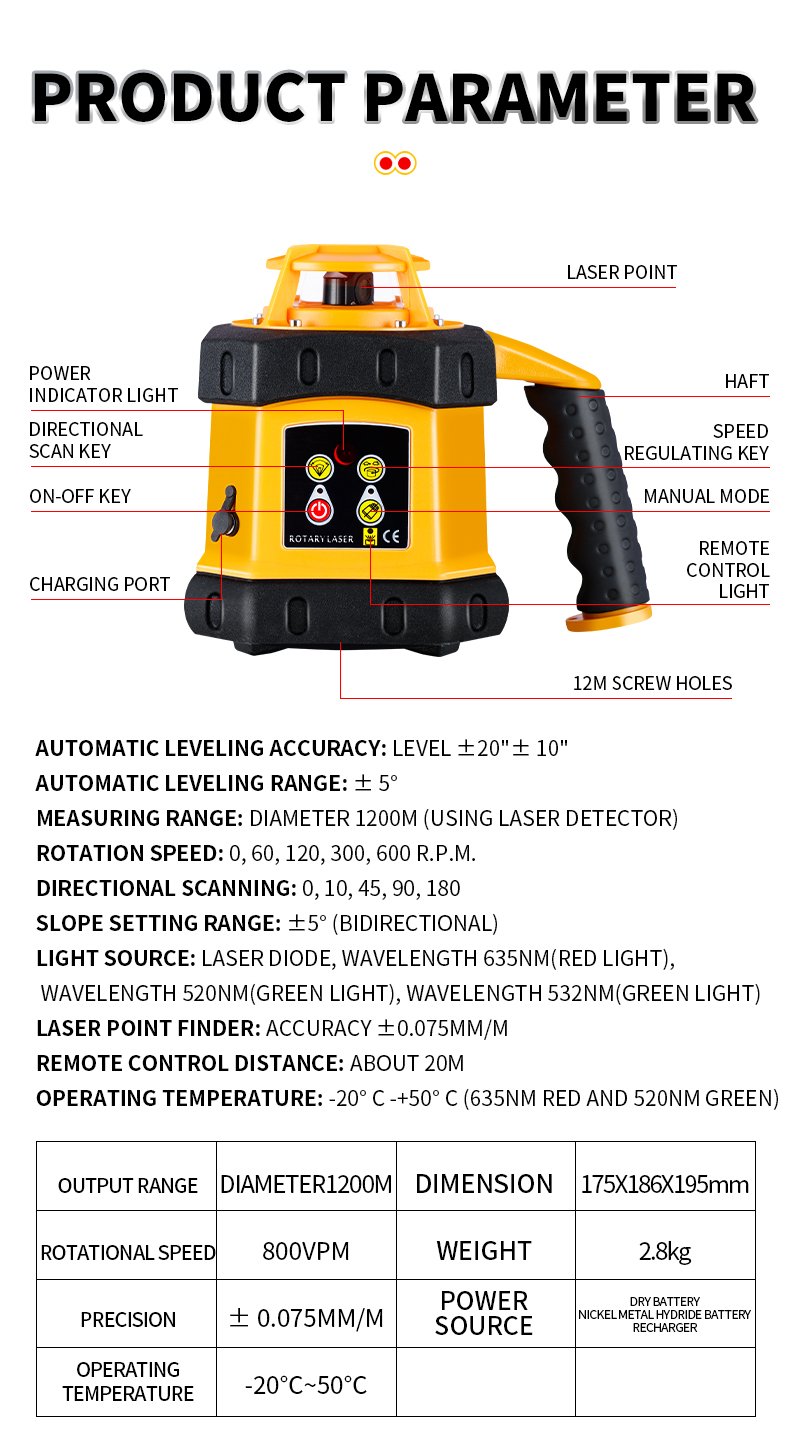

Rotary Laser Levels: These emit a rotating beam of light, creating a 360-degree plane, and are often used for large construction projects.

Line Laser Level:Projects a line onto a surface.

@nx.tools Laser level series products Green light level, infrared level, rotating laser level, etc., high-precision level, clear indoor and outdoor visibility, large battery, long-lasting battery life. #LineLaserLevel #RotaryLaserLevel #Laserlevel #Handtools #Factorysource #madeinchina ♬ 原创音乐 – Nx Tools

3. Leveling a Self-Leveling Laser Level

Stable Surface: Place the laser level on a flat, stable surface such as a tripod, table, or the floor.

Unlock Pendulum: If applicable, disengage the pendulum lock before leveling.

Observe Indicators: Look for visual indicators to determine if the level is within its self-leveling range.

Allow Self-Leveling: The level will automatically adjust itself.

Verify Level: Double-check the leveling indicators.

4. Leveling a Manual Laser Level

Set Up: Place the laser level on a stable surface.

Adjust Screws: Use the leveling screws or knobs to adjust the tilt.

Observe Bubble Vial: Center the bubble within the marked lines on the vial.

Rotate and Repeat: Rotate the level 90 degrees and repeat the adjustment process.

Ensure Stability: Keep the bubble centered regardless of the level’s orientation.

5. Best Practices for Using Laser Levels

Stable Setup: Always set the laser level on a stable surface or tripod to prevent movement that can affect precision.

Tripod Use: A tripod provides a stable and adjustable platform.

Avoid Vibrations: Keep the laser level away from vibration sources.

Allow Stabilization: Give the laser level a few moments to stabilize after adjustments.

Regular Checks: Periodically check the levels during work to catch any discrepancies early on.

Laser Calibration: Ensure the laser level is calibrated to guarantee accuracy in measurements.

Lighting Conditions: Use the laser level in lighting conditions that make the laser lines visible without straining your eyes.

Safety First: Wear safety goggles when operating the laser, and avoid direct eye exposure to the beam.

Equipment Maintenance: Keep the laser level clean and store it properly to extend its lifespan and performance quality.

6. Factors to Consider When Choosing a Laser Level

When selecting a laser level, consider these factors:

Accuracy and Precision: Check the specification for its leveling accuracy.

Laser Range: Consider how far the laser can project; different jobs need different ranges.

Durability: Look for a robust level that can handle knocks and falls.

Battery Life: Long battery life means less downtime.

Ease of Use: It must still be easy to operate, even with advanced features.

Self-Leveling Capability: Self-leveling models save time.

Visibility: Ensure the laser is visible enough for your project, even in bright conditions.

Mounting Options: A good level should mount easily on various surfaces or stands.

Price: Set a budget and weigh the level’s features against its cost.

7. Common Laser Level Problems and Solutions

Power Issues: If the laser level doesn’t turn on, check the battery and charging port.

Physical Damage: Inspect for any damage that might affect performance.

Calibration Issues: If the laser lines are not accurate, perform a calibration test.

8. The Role of a Laser Level Manufacturer

A reputable laser level manufacturer ensures that their tools meet high standards of accuracy and durability. Companies like Topcon, nxtools Level are known for producing reliable laser levels suitable for various applications. When selecting a laser level manufacturer, consider factors such as:

Quality and Reliability: Look for manufacturers with a proven track record of producing accurate and durable laser levels.

Customer Support: Choose a manufacturer that offers excellent customer support and service.

Warranty: Check the warranty offered by the manufacturer to ensure protection against defects.

Technological Innovation: Opt for a manufacturer that incorporates the latest technology into their laser levels.

9. Troubleshooting Leveling Issues

Level Won’t Self-Level:

Make sure the pendulum lock is disengaged.

Ensure that the level is within its self-leveling range.

Check the battery level.

Bubble Won’t Center:

Make sure the level is on a stable surface.

Check the bubble vial for damage or leaks.

Ensure that the leveling screws are not stripped or damaged.

Laser Line is Not Straight:

Check the level’s calibration.

Ensure that the level is properly leveled.

Avoid obstructions in the path of the laser beam.

10. FAQ

Question 1: How do I check the accuracy of my laser level?

Answer: You can check the accuracy by setting it up at a distance from a wall, marking the laser line, rotating the level 180 degrees, and checking if the laser line aligns with the original mark.

Question 2: Can I use a laser level outdoors?

Answer:Yes, but you may need a laser detector to see the beam in bright sunlight.

Question 3: What is the typical self-leveling range?

Answer: Typically around ±4 degrees.

Question 4: How often should I calibrate my laser level?

Answer: Check regularly, especially after any impacts.

Question 5: What are some top brands for laser levels?

Answer: Topcon,nxtools are well-regarded brands.