The construction industry has seen significant advancements in technology, particularly with tools that enhance precision and efficiency. One such tool that has gained prominence is the floor wall tile cross line laser level. This article will explore the importance of this tool, its applications, and why selecting a reputable laser level supplier is crucial for achieving high-quality results in construction projects.

Understanding Cross Line Laser Levels

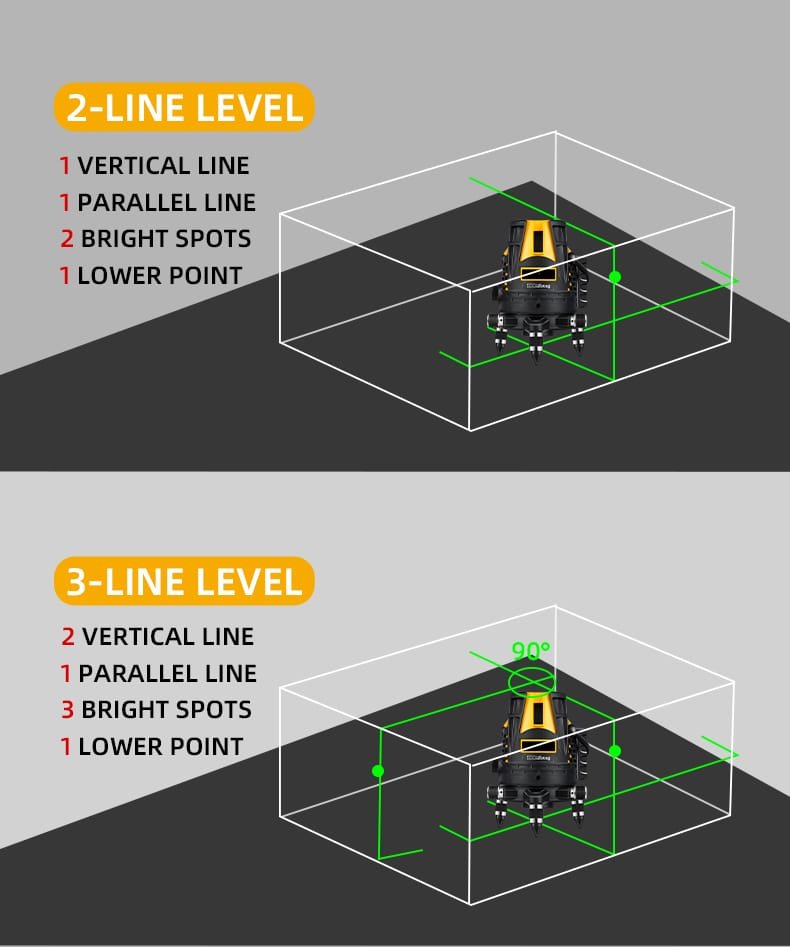

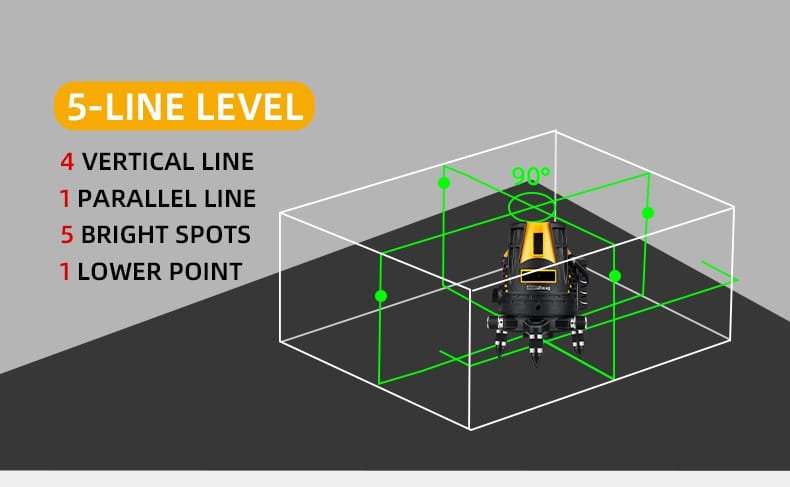

A cross line laser level is a device that projects laser beams to create horizontal and vertical lines on surfaces. This functionality is essential for tasks like installing tiles, where precise alignment is crucial. The laser level ensures that tiles are laid evenly, reducing the risk of costly errors and rework.

Key Features of Cross Line Laser Levels

- Self-Leveling Mechanism: Most modern laser levels come with a self-leveling feature that automatically adjusts the beam to ensure accuracy, even on uneven surfaces.

- Visibility: High-quality laser levels project bright beams (often in green) that are visible even in well-lit environments, making them suitable for various construction settings.

- Range: Many models can project lines over long distances, allowing for greater flexibility in larger areas.

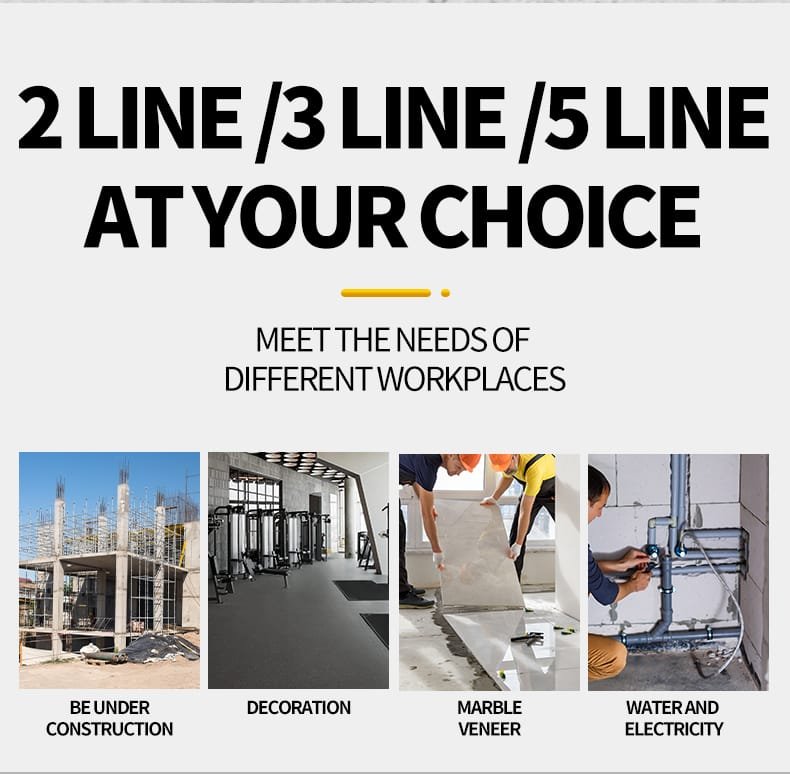

Applications of Floor Wall Tile Cross Line Laser Levels

Using a cross line laser level is particularly beneficial in several construction scenarios:

- Tile Installation: Ensures tiles are aligned correctly, providing a professional finish and preventing future issues with uneven surfaces.

- Wall Framing: Helps in aligning wall studs accurately to maintain structural integrity.

- Cabinet Installation: Assists in ensuring cabinets are level and properly aligned with countertops.

- Landscaping: Used for grading and ensuring proper drainage by establishing level surfaces.

Benefits of Using a Cross Line Laser Level

Utilizing a cross line laser level offers numerous advantages:

- Increased Accuracy: Reduces human error by providing clear visual references for alignment.

- Time Efficiency: Speeds up the process of layout and installation, allowing projects to be completed faster.

- Cost Savings: Minimizes mistakes that can lead to expensive rework, thus saving money in the long run.

Choosing the Right Laser Level Supplier

When selecting a laser level supplier, consider the following factors:

- Reputation: Look for suppliers with positive reviews and a strong track record in the industry.

- Product Range: A good supplier should offer various models to suit different needs and budgets.

- Customer Support: Ensure they provide adequate support, including warranty services and technical assistance.

- Certifications: Verify that the supplier’s products meet industry standards for quality and safety.

How to Use a Floor Wall Tile Cross Line Laser Level Effectively

Using a cross line laser level involves several steps to ensure optimal results:

1. Setup: Position the laser level at the center of the room or area where you will be working.

2. Self-Leveling: Turn on the device and allow it to self-level. This step is crucial for accuracy.

3. Mark Reference Points: Use the projected lines as reference points to mark where tiles will be laid or where walls will be framed.

4. Check Leveling: Regularly check that your work remains aligned with the projected lines as you proceed with installation.

5. Final Adjustments: Make any necessary adjustments based on the laser projections before finalizing installations.

Visual Aids for Using Laser Levels

To enhance understanding, incorporating images and videos demonstrating how to set up and use a floor wall tile cross line laser level can be highly beneficial. These resources provide visual guidance on positioning, leveling, and utilizing the tool effectively during various construction tasks.

The Economic Impact of Laser Level Adoption

The adoption of laser levels has not only transformed operational efficiency but also reshaped economic dynamics within the construction industry. By automating repetitive tasks such as leveling, grading, and alignment, laser levels enable construction teams to work faster and more effectively. This acceleration leads to reduced labor costs and optimized resource allocation across multiple projects simultaneously.

Moreover, enhanced accuracy translates into significant cost savings throughout the construction process. By minimizing errors and ensuring compliance with design specifications, laser levels help prevent costly mistakes that can lead to rework, delays, and budget overruns. Whether it’s ensuring proper foundation alignment or achieving uniform slopes for drainage systems, laser levels enable construction teams to get the job done right the first time, avoiding costly corrections and mitigating financial risks associated with project delays or defects.

Additionally, using laser levels can improve safety on construction sites by reducing the likelihood of accidents caused by manual leveling methods or misaligned structures. With accurate reference points guiding their actions, construction professionals can work confidently while minimizing risks to workers’ safety and property damage.

The Advancement to 3D Laser Levels

As technology continues to evolve, so do laser levels. The introduction of 3D laser levels represents a significant advancement over traditional models. Unlike conventional levels that project a single line, 3D lasers cast multiple lines to create a three-dimensional layout. This capability allows users to level and align objects across all planes—height, width, and depth—making them invaluable for complex projects requiring high precision.

Applications of 3D Laser Levels in Modern Construction

3D laser levels have revolutionized many building tasks by providing high precision planning and guidance:

- Architects use them for setting out floor plans quickly.

- Contractors install walls and utilities right the first time.

- They assist in aligning tiles, cabinets, fixtures, and even complex designs like curved walls.

- Landscapers utilize them for setting grades and drainage systems efficiently.

The ability of 3D lasers to ensure every part of a project aligns perfectly speeds up work processes significantly while cutting down on rework costs.

Steps for Effective Tile Installation Using Laser Levels

To achieve optimal results during tile installation using a cross line laser level:

1. Preparation: Ensure that the surface where tiles will be installed is clean and leveled before starting your work.

2. Setup Your Laser Level:

- Choose an appropriate mode based on your installation needs.

- Securely mount your laser level on a tripod or stable surface.

- Activate self-leveling features if available.

3. Marking Guidelines:

- Use the projected lines from your laser level as guidelines for placing tiles.

- Confirm alignment with your marked reference points regularly.

4. Continuous Monitoring:

- As you place each tile, continuously monitor its position against the projected lines.

- Make adjustments as necessary to maintain alignment throughout the installation process.

5. Final Checks:

- After completing your installation, double-check all tiles for levelness using both your laser level and traditional leveling tools.

- Ensure consistent spacing between tiles using spacers before grout application.

By diligently preparing your tile installation area and utilizing your cross line laser level effectively throughout each step of the process, you can achieve professional results that enhance both aesthetics and durability in your projects.

Conclusion

In conclusion, a floor wall tile cross line laser level is an indispensable tool in modern construction that enhances precision, efficiency, and overall quality of work. By choosing a reliable laser level supplier and understanding how to use this tool effectively, contractors can significantly improve their workflow and ensure professional results across various applications—from tile installation to wall framing.

Frequently Asked Questions

1. What features should I look for when buying a cross line laser level?

- Look for self-leveling capabilities, visibility (preferably green lasers), range (long-distance projection), durability (weather resistance), and ease of use (user-friendly interface).

2. How can I verify the credibility of a laser level supplier?

- Check customer reviews online; request product samples; verify certifications; inspect their manufacturing processes if possible; inquire about warranties offered on products.

3. What are common mistakes when using a laser level?

- Common mistakes include not allowing the device to self-level properly or failing to check alignment regularly during installation tasks; improper setup can lead to inaccurate measurements affecting overall project quality.

4. Can I use a cross line laser level outdoors?

- Yes! However, ensure it has sufficient brightness or outdoor pulse mode for visibility in bright sunlight conditions; some models are specifically designed for outdoor use with enhanced visibility features.

5. How do I maintain my laser level?

- Keep it clean; store it properly when not in use; avoid dropping it or exposing it to extreme conditions; calibrate it regularly as per manufacturer guidelines; check batteries frequently if applicable.

Citations:

[1] https://www.plineasy.com/how-to-use-a-laser-level-for-tile-installation.html

[2] https://www.thisoldhouse.com/tools/22818530/best-laser-level

[3] https://shopintice.com/blogs/news/the-role-of-laser-levels-in-construction-and-surveying

[4] https://www.johnsonlevel.com/Trade/AdoptionofLasersintheCons

[5] https://huepar.com/blogs/huepar-laser-levels/how-to-use-a-laser-level-to-lay-tiles