Utility knives are indispensable tools in various industries and households, prized for their versatility and efficiency. From cutting cardboard boxes to shaping materials in intricate crafts, a reliable utility knife is a must-have. In the heart of China’s hardware tools industry, Yucheng, Shangqiu, NXTools has emerged as a leading utility knife manufacturer. But what exactly makes NXTools’ snap metal utility knives a preferred choice for professionals and DIY enthusiasts alike? This article delves into the features, benefits, and manufacturing excellence that set NXTools apart in a competitive market.

What is a Snap Metal Utility Knife?

A snap metal utility knife, also known as a snap-off blade knife, is a type of cutting tool featuring a segmented blade. These blades are designed with pre-scored lines, allowing users to snap off a dull segment to reveal a fresh, sharp edge. This design ensures consistent cutting performance without the need for frequent blade replacements.

Components and Design

A typical snap metal utility knife consists of:

Handle: Usually made of metal or durable plastic, providing a comfortable and secure grip.

Blade Holder: A mechanism that securely holds the blade in place and allows for easy extension and retraction.

Blade Segments: The segmented blade, typically made of high-carbon steel, offering multiple sharp edges.

Locking Mechanism: A feature that locks the blade in position, preventing accidental retraction during use.

Materials Used

NXTools, as a premier utility knife manufacturer, utilizes high-quality materials to ensure durability and performance. Common materials include:

Blades: High-carbon steel, known for its hardness and ability to hold a sharp edge. Some blades may also be coated with materials like titanium for enhanced durability and corrosion resistance.

Handles: Aluminum, stainless steel, or high-impact ABS plastic, chosen for their strength, lightweight properties, and resistance to wear and tear.

Locking Mechanisms: Steel or reinforced plastic, ensuring reliable blade locking and safety.

Advantages of Snap-Off Blades

The snap-off blade design offers several advantages:

Consistent Sharpness: Easily maintain a sharp cutting edge by snapping off dull segments.

Cost-Effectiveness: Reduces the need for frequent blade replacements, saving time and money.

Safety: Minimizes the risk of injury associated with changing blades, as the process is simple and tool-free.

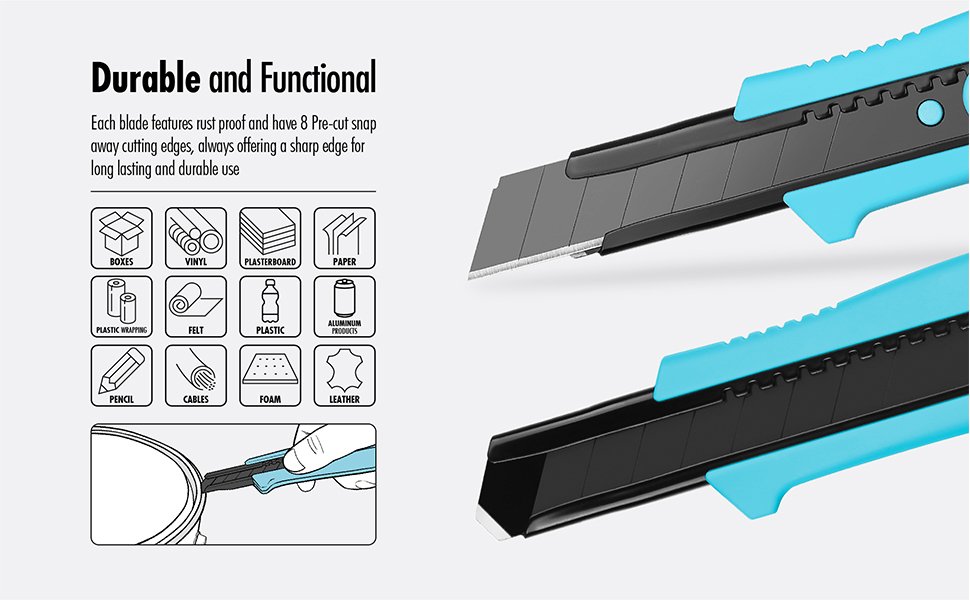

Versatility and Applications

Snap metal utility knives are incredibly versatile, finding applications in various fields:

Cutting cardboard, paper, and plastic

Scoring drywall and other building materials

Stripping wires and cables

Crafting and hobby projects

Company Background: NXTools in Yucheng

Located in Yucheng, Shangqiu, the hardware tools capital of China, NXTools benefits from a rich ecosystem of suppliers, skilled labor, and advanced manufacturing technologies. This strategic location enables NXTools to produce high-quality utility knives at competitive prices.

Manufacturing Capabilities

NXTools operates a state-of-the-art manufacturing facility equipped with:

Precision machining tools for blade production

Injection molding machines for handle fabrication

Automated assembly lines for efficient production

Quality Control Processes

As a reputable utility knife manufacturer, NXTools adheres to stringent quality control processes at every stage of production:

Material Inspection: Ensuring that all raw materials meet strict quality standards.

In-Process Inspection: Monitoring production processes to identify and correct any defects.

Final Inspection: Thoroughly inspecting finished products to ensure they meet performance and safety requirements.

Innovation and R&D

NXTools invests heavily in research and development to stay ahead of market trends and customer needs. The company’s R&D team focuses on:

Developing new blade materials and coatings

Improving handle ergonomics and safety features

Designing innovative locking mechanisms

Detailed Look at NXTools’ Flagship Model(s)

NXTools offers a range of snap metal utility knives, each designed for specific applications. One of their flagship models features:

A durable aluminum handle with a non-slip grip

A high-carbon steel blade with 13 snap-off segments

An auto-locking mechanism for enhanced safety

A built-in blade snapper for convenient segment removal

Blade Material and Hardness

NXTools uses high-carbon steel blades with a hardness rating of HRC 60-62, ensuring excellent cutting performance and edge retention. The blades are also treated with a special coating to enhance corrosion resistance and reduce friction.

Handle Design and Ergonomics

The handles of NXTools utility knives are designed for comfort and control. Features include:

Ergonomic shapes that fit comfortably in the hand

Non-slip grips for secure handling, even in wet conditions

Lightweight materials to reduce fatigue during prolonged use

Safety Features

Safety is a top priority for NXTools. Their utility knives incorporate several safety features:

Auto-locking mechanisms to prevent accidental blade retraction

Blade snappers to safely remove dull segments

Protective caps or sheaths to prevent injury when not in use

Durability and Longevity

NXTools utility knives are built to last. The combination of high-quality materials, precision manufacturing, and rigorous quality control ensures that they can withstand heavy use in demanding environments.

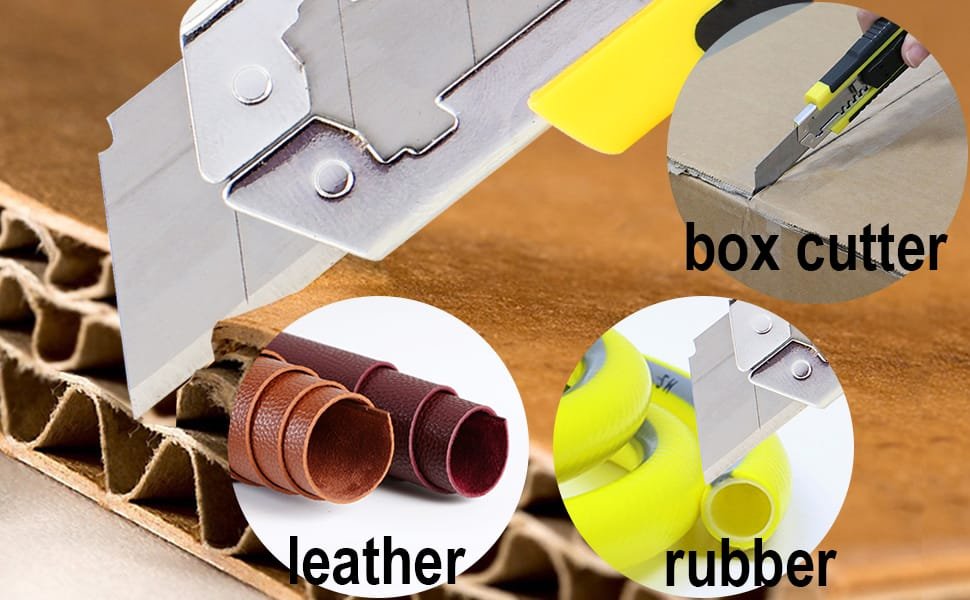

Industrial Use Cases

In industrial settings, NXTools utility knives are used for:

Cutting and trimming materials in manufacturing processes

Opening packages and boxes in warehouses

Installing and repairing equipment

DIY and Home Improvement

For DIY enthusiasts and homeowners, NXTools utility knives are essential tools for:

Cutting drywall, flooring, and other building materials

Removing old caulk and sealant

Preparing surfaces for painting

Crafting and Hobbyist Applications

Crafters and hobbyists rely on NXTools utility knives for:

Cutting paper, fabric, and other materials

Creating intricate designs and patterns

Sculpting and shaping materials

Commercial and Professional Uses

Professionals in various fields use NXTools utility knives for:

Construction workers: Cutting and shaping materials on job sites

Electricians: Stripping wires and cables

Plumbers: Cutting pipes and tubing

Competitive Pricing

NXTools offers competitive pricing without compromising on quality. Their efficient manufacturing processes and strategic location in Yucheng enable them to provide cost-effective solutions for customers worldwide.

Customization Options

NXTools offers a range of customization options to meet specific customer needs:

Custom blade materials and coatings

Custom handle colors and designs

Private labeling and packaging

OEM/ODM Services

NXTools provides OEM/ODM services, allowing customers to develop their own branded utility knives based on NXTools’ proven designs and manufacturing expertise.

Global Distribution and Support

NXTools has a global distribution network, ensuring timely delivery and excellent customer support to customers around the world.

Comparing NXTools with Other Utility Knife Manufacturers

Market Analysis

The utility knife market is highly competitive, with numerous manufacturers offering a wide range of products. NXTools stands out due to its focus on quality, innovation, and customer service.

Strengths and Weaknesses

Strengths:

High-quality materials and manufacturing processes

Competitive pricing

Customization options

Global distribution and support

Weaknesses:

Relatively newer brand compared to established players

Limited brand recognition in some markets

Customer Reviews and Testimonials

Customers consistently praise NXTools utility knives for their sharpness, durability, and ergonomic design. Many customers also appreciate the company’s excellent customer service and customization options.

Smart Utility Knives

The future may see the emergence of “smart” utility knives with features such as:

Built-in sensors to detect cutting force and material type

Automatic blade adjustment for optimal performance

Connectivity to mobile devices for data logging and analysis

Sustainable Materials

As sustainability becomes increasingly important, utility knife manufacturers are exploring the use of eco-friendly materials such as:

Recycled plastics

Biodegradable polymers

Sustainable wood

Ergonomic Innovations

Future utility knives will likely feature even more advanced ergonomic designs to reduce strain and improve user comfort.

Conclusion

In conclusion, NXTools stands out as a leading utility knife manufacturer due to its commitment to quality, innovation, and customer satisfaction. Located in the hardware tools capital of China, NXTools leverages its strategic location, advanced manufacturing capabilities, and rigorous quality control processes to produce high-performance snap metal utility knives that meet the needs of professionals and DIY enthusiasts alike.

So, what makes NXTools’ snap metal utility knives a top choice? It’s the combination of superior materials, innovative design, competitive pricing, and excellent customer service.

Contact NXTools today to learn more about their snap metal utility knives and how they can meet your cutting needs!

Q&A Section

Q1: What types of blades does NXTools offer for its utility knives?

A: NXTools offers high-carbon steel blades with various coatings, such as titanium, for enhanced durability and corrosion resistance. The blades are available in different thicknesses and segment configurations to suit various applications.

Q2: Can I customize the handle of my NXTools utility knife?

A: Yes, NXTools offers customization options for handle colors, materials, and designs. They can also add your company logo or branding to the handle.

Q3: Does NXTools offer OEM/ODM services?

A: Yes, NXTools provides OEM/ODM services, allowing you to develop your own branded utility knives based on their designs and manufacturing expertise.

Q4: What safety features are included in NXTools utility knives?

A: NXTools utility knives incorporate several safety features, including auto-locking mechanisms, blade snappers, and protective caps or sheaths.

Q5: How can I become a distributor of NXTools utility knives?

A: To become a distributor, please contact NXTools directly through their website or sales department. They will provide you with information about their distribution program and requirements.