Introduction: The Importance of Ergonomic Utility Knives in Today’s Work Environment

In fast-paced industrial and commercial environments, the tools we use can directly impact productivity, safety, and worker satisfaction. Utility knives, commonly used for cutting, scraping, and trimming, are essential in numerous industries. However, the traditional designs of utility knives often lead to discomfort, fatigue, and even injury during prolonged use. Enter ergonomic utility knives—designed with comfort and safety in mind, these tools have revolutionized workplaces by improving both efficiency and worker well-being.

As a leading industrial company, Nxtools specializes in developing and producing high-quality ergonomic hand tools. Their commitment to innovation and worker safety has made them a prominent player in the global market. This article explores the importance of ergonomic utility knives, focusing on their design features, benefits, and the manufacturing processes involved in creating these indispensable tools.

What Makes a Utility Knife “Ergonomic”?

The term “ergonomic” refers to designing products that fit the user’s body and movements, reducing strain and enhancing comfort. In the case of utility knives, ergonomic designs incorporate various features that improve the user’s grip, minimize fatigue, and prevent injuries.

Key Features of Ergonomic Utility Knives:

- Handle Design: Ergonomically designed handles are typically contoured to fit the natural shape of the hand. Materials like rubber, soft plastics, or molded polymers offer a non-slip grip, reducing strain on the wrist and fingers.

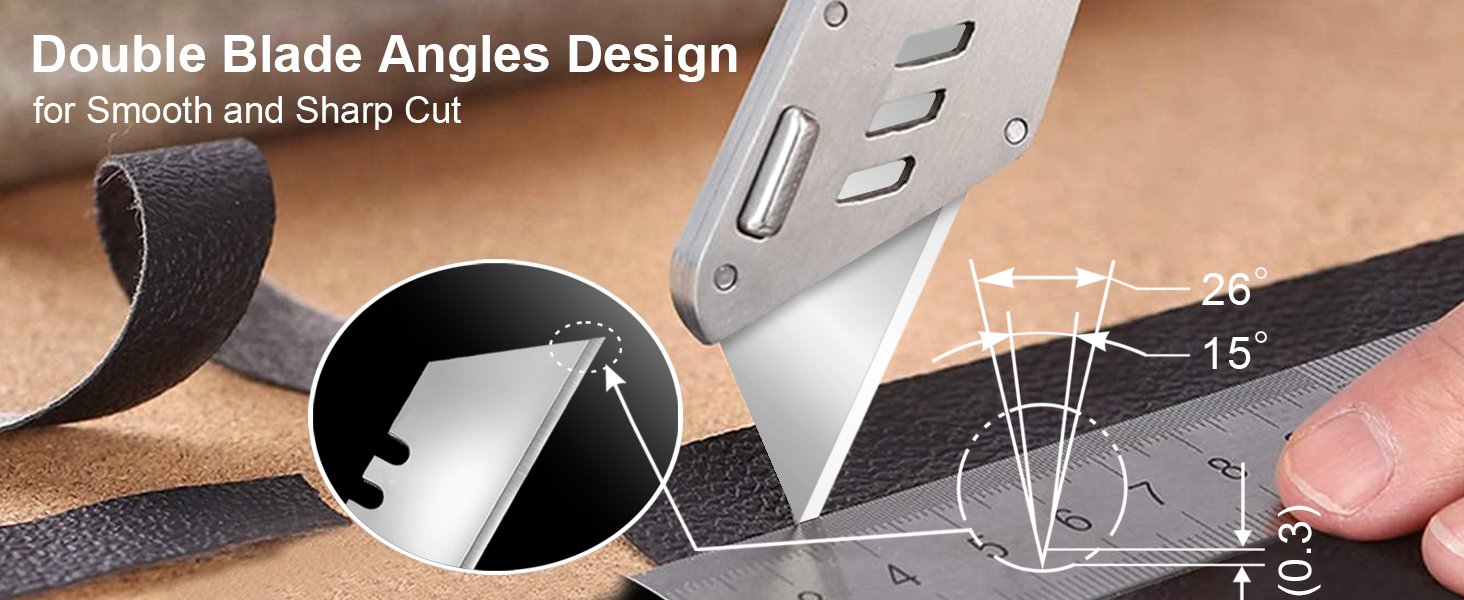

- Blade Mechanism: The blade should be easy to replace and lock securely to prevent accidents. A retractable or auto-locking blade mechanism adds an additional layer of safety.

- Weight and Balance: Ergonomic utility knives are designed to be lightweight yet durable, with a balanced weight distribution to reduce strain on the hand and wrist.

How Do Ergonomic Utility Knives Improve Worker Productivity?

Ergonomic utility knives offer several key benefits that directly impact productivity:

- Reducing Fatigue: Ergonomically designed handles reduce the amount of force required to hold and maneuver the knife, allowing workers to use the tool for longer periods without experiencing fatigue.

- Minimizing Repetitive Strain Injuries (RSIs): Long-term use of poorly designed tools can lead to conditions like carpal tunnel syndrome or tendinitis. Ergonomic utility knives reduce the risk of these injuries by promoting a more natural grip and reducing the repetitive strain on joints.

- Improving Precision: A comfortable grip leads to more control, which translates into greater cutting precision. This is especially important in industries that require high levels of accuracy, such as packaging, construction, and crafting.

What Are the Key Design Features of Ergonomic Utility Knives?

Several elements go into the design of an ergonomic utility knife. These include:

- Handle Shape: A well-designed handle will feature contours that match the shape of the hand and provide a secure, comfortable grip.

- Materials: Soft-touch materials like rubber or TPE (thermoplastic elastomers) provide a better grip while minimizing hand fatigue.

- Blade Features: Quick-change or retractable blades ensure that users don’t need to exert extra force during blade replacement or adjustment.

- Safety Features: An ergonomic utility knife often includes a blade-locking mechanism that prevents accidental exposure of the blade.

What Benefits Do Ergonomic Utility Knives Offer to Employers and Workers?

1. Worker Safety: Ergonomically designed knives reduce the risk of injuries, including cuts, punctures, and repetitive stress injuries.

2. Worker Satisfaction: A more comfortable tool leads to higher worker satisfaction and morale, ultimately boosting productivity.

3. Cost-Effectiveness: Although ergonomic utility knives may have a higher upfront cost, their durability and ability to reduce workplace injuries can save companies money in the long run.

Why Is the Manufacturing Process Critical for Ergonomic Utility Knives?

A utility knife factory must adhere to stringent quality standards when manufacturing ergonomic tools. The precision involved in shaping the handles, ensuring the blades are securely fixed, and using high-quality materials is crucial for creating durable, safe tools. Nxtools, for example, utilizes state-of-the-art manufacturing facilities that employ advanced technology to produce ergonomic utility knives that meet international standards.

How to Choose the Right Ergonomic Utility Knife for Your Needs?

Choosing the right utility knife involves considering:

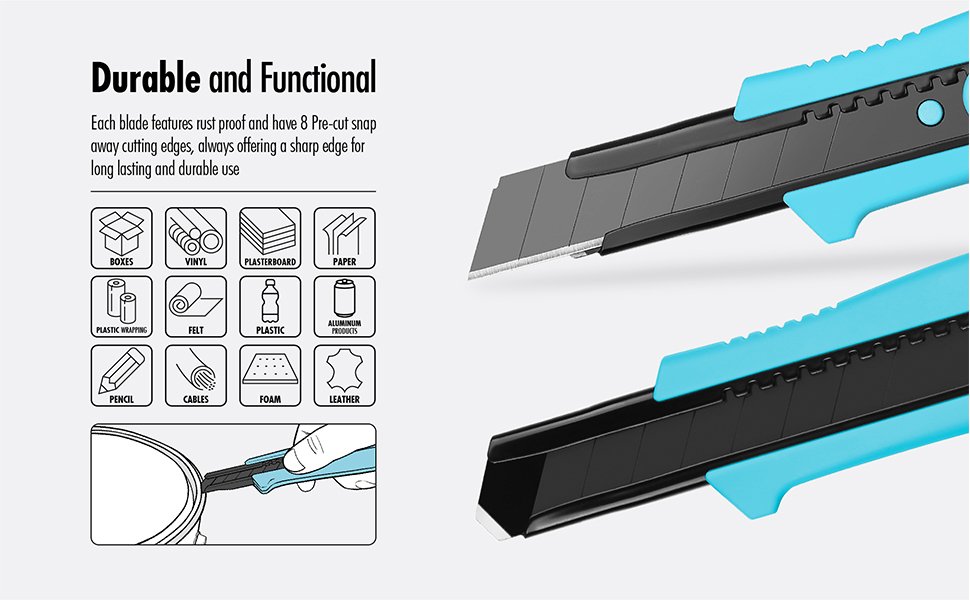

- The Type of Work Being Done: Different industries may require different blade types and safety features.

- Grip and Comfort: For prolonged use, a well-designed ergonomic grip is essential.

- Durability and Safety: Look for knives with strong locking mechanisms, durable blades, and high-quality materials.

Where Are Ergonomic Utility Knives Commonly Used?

Ergonomic utility knives are used in various industries, including:

- Construction Sites: For cutting materials like drywall, insulation, and plastic.

- Packaging: To cut boxes and shrink wrap efficiently and safely.

- Crafting and DIY: For precision cutting in artistic and creative work.

- Maintenance and Repairs: For everyday tasks like stripping wires and cutting wires or cables.

What Are the Common Maintenance Practices for Ergonomic Utility Knives?

To ensure the longevity of your ergonomic utility knife:

- Regular Cleaning: Clean your knife after each use to prevent buildup of cutting debris.

- Blade Replacement: Always replace dull blades promptly to maintain efficiency and safety.

- Safe Storage: Store knives in a safe, dry place to avoid damage and accidental injury.

Conclusion: The Growing Demand for Ergonomic Utility Knives in the Industrial Sector

The demand for ergonomic utility knives continues to grow as businesses recognize their value in enhancing productivity, improving safety, and increasing worker satisfaction. As a leading utility knife manufacturer, Nxtools plays a vital role in supplying ergonomic tools that meet the needs of modern industries.

Frequently Asked Questions

- What is an ergonomic utility knife? An ergonomic utility knife is designed with features that reduce fatigue and prevent injuries, offering a more comfortable and efficient cutting experience.

- How do ergonomic utility knives improve safety? By featuring comfortable handles, non-slip grips, and safety locking mechanisms, ergonomic utility knives reduce the risk of accidents in the workplace.

- Can ergonomic utility knives prevent injuries? Yes, ergonomic designs help reduce strain and the risk of repetitive stress injuries, making them ideal for extended use.

- What industries benefit most from ergonomic utility knives? Industries such as construction, packaging, and crafting benefit greatly from the comfort and safety provided by ergonomic utility knives.

- How do I maintain my ergonomic utility knife? Regular cleaning, blade replacement, and proper storage are essential to keep your ergonomic utility knife functioning at its best.