In the realm of industrial and commercial tools, utility knives are indispensable. Among the many brands available, Toughbuilt stands out as a leader in innovation and quality. Based in Yucheng, Shangqiu—known as the hardware tools capital of China—Nxtools operates a modern manufacturing facility that specializes in high-quality hand tools, including Toughbuilt utility knives. This article delves into the features, benefits, and applications of Toughbuilt utility knives while exploring their significance in various industries.

Understanding Toughbuilt Utility Knives

What is a ToughBbuilt Utility Knife?

A Toughbuilt utility knife is designed for versatility and durability. These knives are crafted to handle a wide range of cutting tasks, making them essential tools for professionals in construction, manufacturing, and other demanding environments. The innovative designs incorporate ergonomic features that enhance user comfort and safety.

Key Features of Toughbuilt Utility Knives

1. Quick-Reload Mechanism: Many Toughbuilt models feature a patented quick-reloading blade mechanism that allows users to change blades swiftly with the flick of a switch. This efficiency is crucial in fast-paced work environments.

2. Ergonomic Design: The knives are designed with non-slip rubber handles that provide a comfortable grip, reducing hand fatigue during prolonged use.

3. Safety Features: Toughbuilt utility knives often include safety mechanisms such as blade guards and finger guards to protect users from accidental cuts.

4. Versatile Blade Options: Toughbuilt offers various blade types, including straight-edge and hook blades, allowing users to choose the right blade for specific tasks.

5. Durable Construction: Made from high-quality materials like aluminum alloy and zinc alloy, Toughbuilt knives are resistant to corrosion and wear, ensuring longevity even under tough conditions.

The Role of Nxtools as a Utility Knife Manufacturer

Company Overview

Nxtools is recognized as a leading manufacturer and supplier of utility knives in China. The company focuses on developing innovative tools that meet the needs of professionals across various industries. With its state-of-the-art manufacturing facility, Nxtools ensures that every Toughbuilt utility knife adheres to stringent quality standards.

Manufacturing Process at Nxtools

The production of Toughbuilt utility knives at Nxtools involves several key steps:

1. Material Selection: The company sources high-quality materials to ensure durability and performance.

2. Design Development: Engineers collaborate with designers to create ergonomic models that enhance user experience.

3. Precision Manufacturing: Advanced machinery is utilized to manufacture components with high precision.

4. Quality Assurance: Each product undergoes rigorous testing to ensure it meets safety and performance standards before reaching the market.

Benefits of Using Toughbuilt Utility Knives

Increased Efficiency

Toughbuilt utility knives are designed for quick blade changes and comfortable handling, allowing professionals to work more efficiently without interruptions.

Enhanced Safety

With built-in safety features, these knives minimize the risk of accidents, making them suitable for various work environments where sharp tools are used frequently.

Versatility

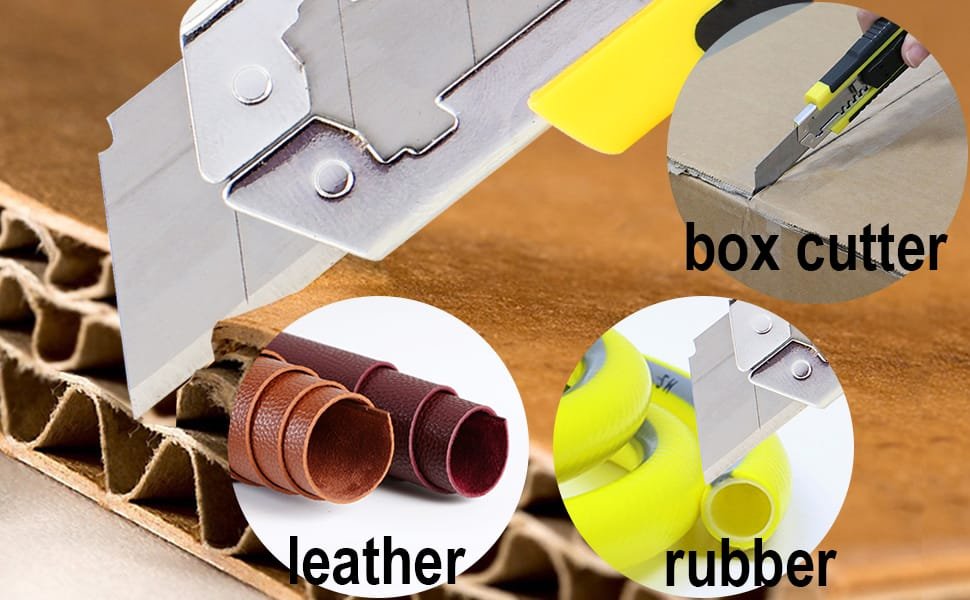

Toughbuilt utility knives can handle a wide range of materials—cardboard, plastic, rope, carpet—making them versatile tools for different tasks.

Cost-Effectiveness

Investing in high-quality utility knives reduces the need for frequent replacements. The durability of Toughbuilt products ensures they withstand heavy use over time.

Applications of Toughbuilt Utility Knives

Toughbuilt utility knives find applications in numerous industries:

– Construction: Essential for cutting drywall, insulation, and packaging materials.

– Manufacturing: Used on assembly lines for various cutting tasks.

– Logistics: Ideal for unpacking shipments quickly and efficiently.

– Crafting: Popular among hobbyists for precision cutting in arts and crafts projects.

– Retail: Useful for opening boxes and cutting packaging materials safely.

Case Study: Toughbuilt Utility Knives in Construction

In construction environments where efficiency is paramount, Toughbuilt utility knives have proven invaluable. A study conducted on various construction sites revealed that teams using Toughbuilt knives reported a 30% increase in productivity due to faster blade changes and reduced hand fatigue compared to those using standard models.

Comparing Toughbuilt Utility Knives with Other Brands

When evaluating different brands of utility knives, it’s essential to understand how Toughbuilt compares with competitors:

| Feature | Other Brands | Toughbuilt |

|—————————–|————————|————————-|

| Quick Blade Change | Manual | Patented quick-reload |

| Grip Comfort | Basic | Ergonomic non-slip grip |

| Safety Features | Minimal | Comprehensive safety |

| Blade Variety | Limited | Multiple options |

| Durability | Variable | High-quality materials |

As shown in this comparison table, Toughbuilt utility knives offer significant advantages over many competing brands.

Maintenance Tips for Toughbuilt Utility Knives

To ensure longevity and optimal performance from your Toughbuilt utility knife, consider these maintenance tips:

1. Regular Cleaning: Clean the knife after each use to prevent residue buildup that can affect performance.

2. Blade Replacement: Replace blades regularly to maintain sharpness; dull blades require more force, increasing injury risk.

3. Inspect Safety Features: Regularly check all safety mechanisms to ensure they function correctly.

4. Proper Storage: Store your knife in a designated area when not in use to prevent damage or accidents.

Frequently Asked Questions (FAQs)

1. What should I look for when choosing a utility knife?

– Look for features like quick blade changes, ergonomic design, safety mechanisms, and durable materials.

2. How do I change the blade on a Toughbuilt utility knife?

– Most models feature a quick-release button or mechanism that allows you to change blades easily without additional tools.

3. Can I use different types of blades with my Toughbuilt knife?

– Yes! Toughbuilt utility knives are compatible with various blade types including straight-edge and hook blades.

4. Are Toughbuilt utility knives safe for all users?

– Yes! They are designed with safety features that minimize risks associated with cutting tools.

5. How do I maintain my Toughbuilt utility knife?

– Regularly clean it after use, replace dull blades promptly, check safety features periodically, and store it properly when not in use.

6. What industries benefit most from using Toughbuilt utility knives?

– Industries such as construction, manufacturing, logistics, crafting, and retail benefit significantly from these versatile tools.

7. How does Nxtools ensure the quality of its products?

– Nxtools employs strict quality control measures throughout the manufacturing process to ensure all products meet high standards.

8. What is the average lifespan of a Toughbuilt utility knife?

– With proper care and maintenance, these knives can last several years even under heavy use conditions.

9. Are there any warranties available for Toughbuilt products?

– Yes! Many Toughbuilt products come with warranties that cover defects in material or workmanship.

10. Where can I purchase Toughbuilt utility knives?

– They are available through various retailers both online and in physical stores specializing in tools and equipment.

Conclusion

Toughbuilt utility knives represent a significant advancement in tool design aimed at enhancing worker efficiency and safety across various industries. As a leading manufacturer based in Yucheng, Shangqiu—Nxtools ensures that every product meets stringent quality standards while providing innovative solutions for professionals worldwide. Investing in high-quality utility knives like those offered by Toughbuilt will undoubtedly lead to better outcomes for both workers and employers alike.

With their proven benefits—from increased productivity to enhanced safety—Toughbuilt utility knives are not just tools; they are essential investments into creating safer and more efficient work environments.